Belt Conveyor Pulleys are one of the most versatile components of a conveyor system. As conveyor pulley manufacturer in China, SKE Industries offers a wide range of conveyor pulleys designed for bulk material handling belt conveyors. Our portfolio includes drive pulleys, tail pulleys, wing pulleys, and bend pulleys, engineered for durability and efficiency in industries like mining, quarry, ports, power, steel and more.

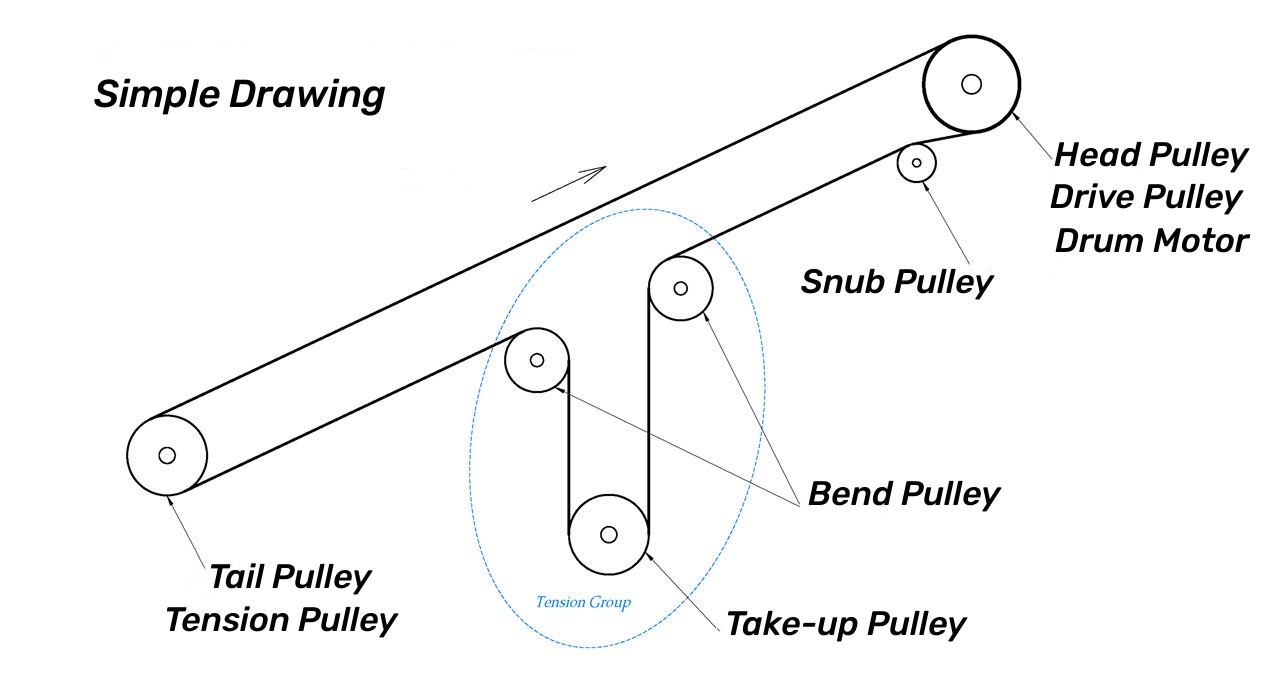

The head pulley is located at the discharge point. It usually drives the belt and often has a larger diameter than other pulleys. If the conveyor adopts a mid-drive design, the head pulley does not have a driving role.

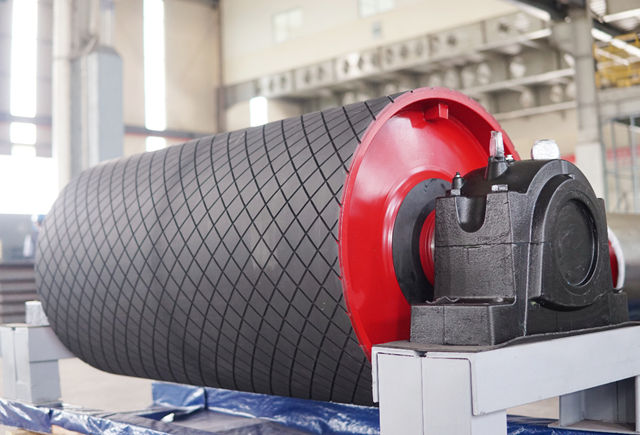

A Drive Pulley is used for the purpose of driving a conveyor belt. They are normally mounted in external bearings and driven by a motor and gearbox. A drive drum pulley has rubber or ceramic lagged.

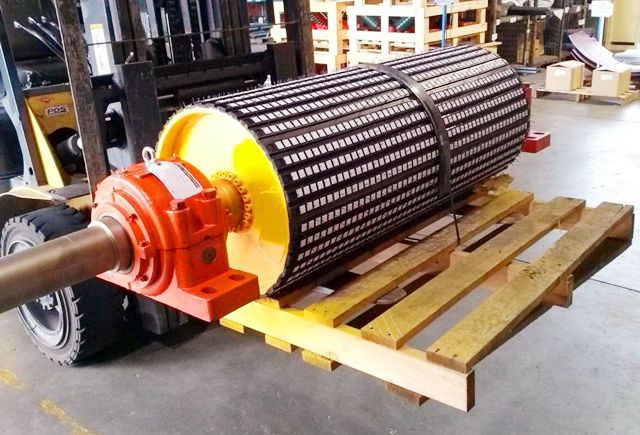

Belt Conveyor Motorized Pulley is a type of belt conveyor driving units. This drum motor needs smaller space for driving belt conveyor systems. The usage frequency of drum motors in projects is constantly increasing.

A snub pulley improves the traction of the drive pulley by increasing its belt wrap angle. The diameter of the snub pulley is much smaller than head pulley. We offer lagged conveyor snub pulleys.

The Belt Conveyor Bend Pulley is frequently used as tail pulley, take-up pulley, and snub pulley to change the belt running direction. It plays an important role in a conveyor belt.

A take-up pulley is used to provide the belt with the proper amount of conveyor belt tension. It is often used in belt conveyor gravity tension system and screw tension system. Its position is adjustable.

The conveyor tail pulley is located at the loading end of the belt. It comes with either a flat face or a slatted profile (wing pulley). Tail pulleys are used to redirect a conveyor belt back toward the drive pulley.

The wing pulley is also known as self-cleaning pulleys, and wing pulleys are primarily used on the tail end of bulk handling systems. We provide mine duty and quarry duty wing pulleys.

The lagged pulley can be head pulley, tail pulley, take-up pulley, bend pulley, etc. We offer ceramic lagged pulley, plain rubber lagged pulley, diamond grooved lagged pulley, spiral grooved lagged pulley, etc.

60000

Factory (㎡)

100+

Workers

20+

R&D Engineers

20+

Welders Certified

160+

Marketing Areas

1000+

Projects

Our drum pulleys are made of steel to create a durable shell and are normally crowned to facilitate greater belt contact. Wing pulleys are fabricated with a non-continuous contact surface and open voids that allow loose material to fall. There are five classes available:

A pulley bushing is a component used in conveyor pulley systems to connect the pulley to the shaft. The bushing serves as an intermediary between the pulley and the shaft, providing a secure and often adjustable connection. The bushing types:

The pulley hub is a central component of a conveyor pulley, serving as a connection point between the pulley shell and the shaft. It plays a crucial role in transmitting the rotational force from the shaft to the pulley shell, enabling the movement of the conveyor belt.

Pulley lagging is a protective layer applied to the surface of a conveyor pulley to improve traction between the pulley and the conveyor belt. We offer conveyor pulleys coated with materials like SBR, SOF, SAR, MSHA, Neoprene, Urethane, Husky, Static Conductive Neoprene, or Cold Bond Rubber Lagging .

| Chevron-Compound | Herringbone-Compound |

|

|

| Smooth-Compound | Holz Slide Lag-Compound |

|

|

| Ceramic-Compound | Urethane-Compound |

|

|

The most complete product range on the market to maximize output and safety of your conveyor operations.

Dedicated to keeping your operation as productive and profitable as possible.

Durable conveyor parts designed for long component life.

Smart, simple design that makes parts efficient, robust and maintenance friendly.