Belt Cleaners are engineered to clean bulk material from conveyor belts thoroughly and can accommodate belt widths up to 120 inches (3,000 mm) with belt speeds up to 2,000 fpm (10 m/s). SKE provide primary and secondary heavy duty mine and light industrial conveyor belt cleaner system.

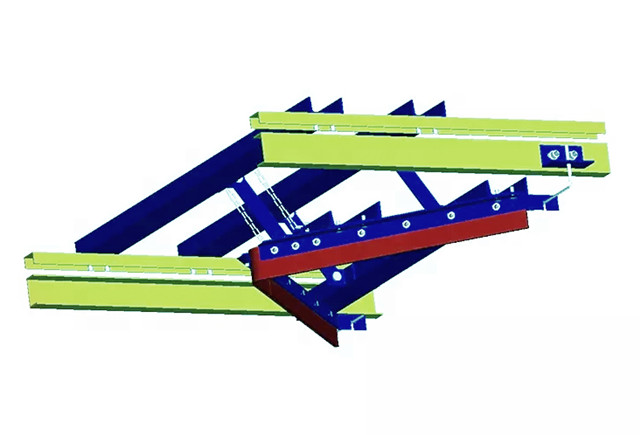

SKE is a top manufacturer of V return belt cleaner. V-Plow Belt Cleaners remove material from the belt before it enters the tail pulley. V-Plows are an economical choice for belts that run in just one direction.

SKE is a top manufacturer of secondary belt cleaner. This group of belt scrapers is engineered to remove the residual fines that remain on the belt past the primary cleaner in a multi-scraper system.

SKE is a top manufacturer of primary belt cleaner. Installed on the face of the head pulley just below the trajectory of the discharging payload, primary belt cleaners peel-off most of this carryback.

SKE Industries is belt cleaner manufacturer in China. We have over 13 years of experience in providing conveyor belt cleaning solutions. Belt cleaners are an integral part of your belt conveyor system because of their ability to remove carryback from your belt. Carryback is a major problem on many conveyors, requiring frequent cleaning, while it also can prematurely wear out our conveyor components and cause other conveying issues, such as belt misalignment. Reducing carryback can improve worker safety, increase operating efficiency, and enhance productivity. The common applications:

| Scraper Belt Cleaners | Use a blade (polyurethane or tungsten carbide) to scrape material off the belt surface. |

| Brush Belt Cleaners | Utilize brushes to sweep away fine particles and dust. |

| Belt Plows | Direct material off the side of the conveyor belt. |

| Air Knife Systems | Systems incorporate air knife technology. |

Choosing the right conveyor belt cleaner depends on factors such as the type of material being transported, conveyor system specifications, and environmental conditions. We need you provide some information listed below to choose a model for you.

* The condition of the belt is crucial for the effectiveness of the cleaner.

A. Belt Width, B. Frame Width, C. Pulley Diameter, D. Material Path Width.

Many belt cleaners are adjustable to accommodate different belt widths and angles. This ensures a proper fit for various conveyor systems.

Cleaner blades are often made of wear-resistant materials like polyurethane, tungsten carbide, or other wear-resistant materials.

Some of our conveyor belt cleaners have a tensioning mechanism to maintain consistent pressure on the belt for optimal cleaning performance.

Regular cleaning removing sticky materials helps extend the life of the conveyor belt.

Prevents material-related issues that can lead to downtime, such as belt slipping and belt misalignment.

Reduces the risk of accidents and damage associated with material buildup.