The telestacker is a type of telescopic conveyor which is widely used in handling bulk materials. It has telescopic unit to extend the working length and improve the stockpiling efficiency. This telestacker conveyor can be mounted on wheels and tracks. Its variable height, length, and axle positions allow for layered stockpile construction, which is key to achieving partially and fully desegregated piles.

Obtained Certificates: CE Certificate, ISO 9001, ISO 14001, ISO 45001,

The stacking volume is 209,300 yd³(160,021m³). The stockpiling capacity is up to 5000 tons per hour. The stockpile height of this telestacker conveyor is up to 66ft.

The stacking volume is 142,400 yd³(108872m³). The stockpiling capacity is up to 4000 tons per hour. The stockpile height of this telestacker conveyor is up to 58ft.

The stacking volume is 104,300 yd³(79,743m³). The stockpiling capacity is up to 4000 tons per hour. The stockpile height of this telestacker conveyor is up to 50ft.

The stacking volume is 76,500 yd³(58,488m³). The stockpiling capacity is up to 1500 tons per hour. The stockpile height of this telestacker conveyor is up to 43ft.

The stacking volume is 69,300 yd³(52,983m³). The stockpiling capacity is up to 1500 tons per hour. The stockpile height of this telestacker conveyor is up to 43ft.

The stacking volume is 49,200 yd³ (37,616m³). The stockpiling capacity is up to 1500 tons per hour. The stockpile height of this telestacker conveyor is up to 39ft.

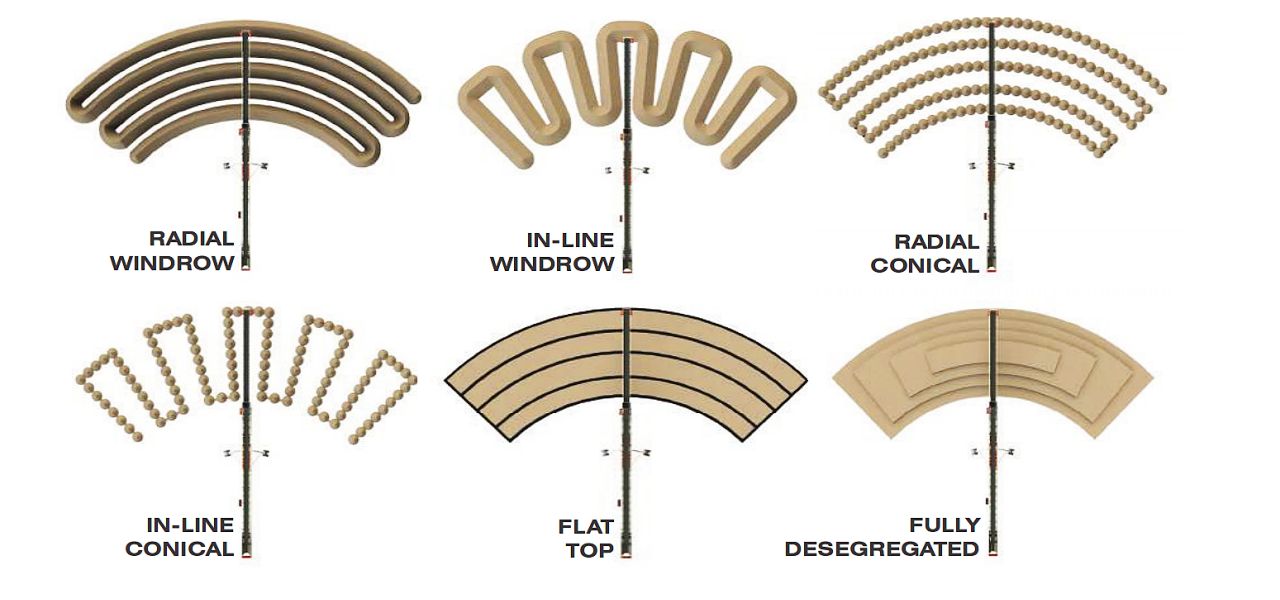

Radial Windrow Stacking, In-line Windrow Stacking, Radial Conical Stacking, Flat Top Stacking and so on.

You can use these telescopic stockpilers to build the different high-quality stockyard.

The Telestacker conveyor can be moved by crawler. It can adapt to different types of terrains. This track-mounted radial telescopic stacking conveyor can be widely used in stockyards, ports and in-land terminals.

You can use the Pivot point as the prototype, make an arc slewing. You can use a truck to transport it. It can be used in fixed staking system. It also can be fixed onto horizontal conveyors for ore heap leaching.

Both made of heavy duty fabricated steel. Both designed for highest capacity, highest tonnage applications and towing within the quarry site.

The hydraulically transferring stacker from inline to radial mode in seconds. It is also suitable for highest capacity and highest tonnage applications.

To operations where segregation is an issue, TeleStacker Conveyors prevent deduct penalties and save costs with restoring in-spec material.

Our automation fills out the back of a stockpile, resulting in 30% more material on the same footprint.

Designed in-house – which means faster support when you need it – our Automation is easy to set up and simple to operate.

A heavy-duty design means we’ve got a deeper truss, a robust undercarriage, and more cross bracing.