Belt Conveyor Idler is an important part of the belt conveyor. Conveyor idlers are designed to support the weight of the conveyor belt and the materials being transported. SKE is a conveyor idlers manufacturer, and you can get conveyor idlers designed by using standards like ISO, UNI, DIN, AFNOR, FEM, BS, JIS, AS, SANS and CEMA from us.

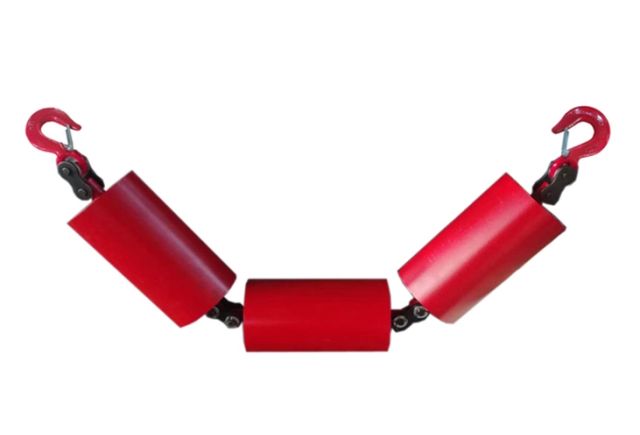

The garland idler is typically made of high-quality steel or stainless steel. The garland idlers were originally developed to improve belt conveying for large conveying capacities and large lumps.

Troughed idlers are the most common idlers used on the carry side of the conveyor. Troughed idlers are designed to form a trough shape in the conveyor belt to contain and guide bulk materials. SKE troughing idlers come in 20°, 35°, and 45°.

Belt conveyors return idlers are used to support the belt as it cycles around to be loaded again. Standard Return Idlers are available with one steel rollers or two steel rollers.

Impact idlers are designed with rubber which absorb impact forces minimizing belt damage. Our impact idlers are used in impact areas where belt damage is common.

As the name suggest, these idlers are used to carry belt with bulk materials. Belt conveyor carrying idlers are used to carry conveyor belt and support bulk materials on conveyor belt working surface.

Self-aligning idlers are designed to automatically adjust and maintain the alignment of the conveyor belt. They help prevent belt misalignment issues and ensure smooth operation.

In feeder applications, wide coverage is needed. The flat return idler is the most common conveyor idler. We provide conveyor flat idler working as carrying idler and return idler.

This steel spiral return conveyor idlers are also called self-cleaning idlers, and they can clean the sticky materials on the conveyor belts. They are used on the return side of the belt as belt cleaner.

The rubber disc return idlers are used where sticky materials adhere to the belt and a corrosive environment. SKE rubber disc return idlers can assist by removing carryback of belt.

Conveyor idlers are a crucial component of belt conveyors, which are widely used in industries for the transportation of bulk materials such as grains, ores, coal, and more. Idlers are cylindrical rollers or sets of rollers located at regular intervals along the conveyor belt.

60000

Factory (㎡)

100+

Workers

20+

R&D Engineers

20+

Welders Certified

160+

Marketing Areas

1000+

Projects

| Conveyor Idler Standard | CEMA(CEMA B, C, D, E, F), DIN, ISO, GB, AS, GOST, SANS, etc. |

| Conveyor Idler Material | The conveyor idlers are used for support conveyor belt. The supporting bracket material can be:

|

| The Idler Design Consideration | Proper selection and placement of idlers contribute to belt stability, alignment, and overall system efficiency. Design Consideration:

|

| Conveyor Idler Supporting | The conveyor idler roller bracket provides structural support to the conveyor belt.

|

| Conveyor Idler Roller Numbers | They can include 1 roll, 2 rolls, 3 rolls, 5 rolls, and 6 rolls in a conveyor idler . |

| Conveyor Idler Trough Angle | 0, 10°, 20°, 35°, 45°. |

Conveyor equipment built for optimal performance. Supported by premium bearings and effective seals, Our idlers deliver superior outcomes on-site.

Decades of craftsmanship and quality manfacturing go into making our idlers highly durable. They stand up to heavy-duty demands and promote long belt life.

Idlers are available in a variety of designs, widths, diameters and angles allowing for high flexibility in conveyor design.