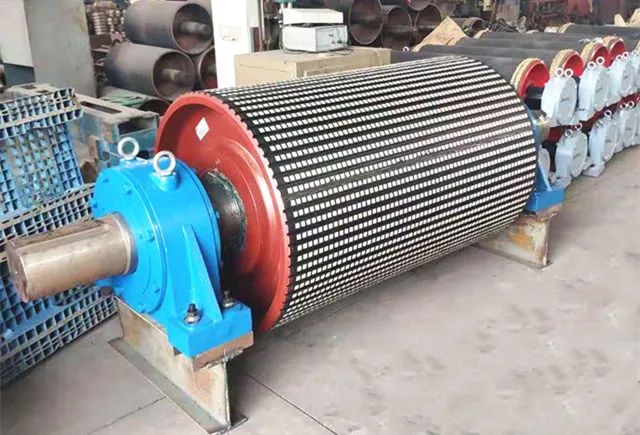

A lagged conveyor pulley is a pulley on a belt conveyor system that has a layer of material applied to its surface. SKE offer conveyor drum pulleys with plain rubber, diamond grooved rubber, or ceramic rubber lagged.

The lagged material services several purposes, primarily related to improving the friction and grip between the pulley and the conveyor belt. It is an important component that helps prevent belt slippage, enhances overall system efficiency, and protects the pulley from wear.

The lagged conveyor pulley can be head pulley, tail pulley, take-up pulley, snub pulley, and bend pulley. Lagged conveyor drum pulleys can be used in various industries, including mining, aggregate, port, power, steel, bulk material handling, and more.

Diamond Profile Rubber lagged pulleys. Diamond grooved lagging features a pattern of diamond-shaped grooves on the lagging surface. This design improves traction and helps to channel water and debris away from the pulley, preventing slippage.

Ceramics & Profile Rubber lagged pulleys. Ceramic lagging incorporates ceramic tiles embedded in a rubber matrix. This combination enhances wear resistance and provides additional grip, making it suitable for applications involving abrasive materials.

Herringbone Profile Rubber lagged pulleys. Herringbone lagging has a pattern of diagonal grooves resembling a herringbone. This design helps to improve the grip between the pulley and the belt.

Plain and Smooth Rubber lagged pulleys. Plain Rubber Lagging for non-drive pulleys to provide better traction for the conveyor belt. Plain rubber lagging is a common and versatile choice for conveyor drum pulleys.

| Belt Conveyor Lagged Pulley Specification | |

| Belt Width | 500-2800mm (19-110.2 inch) |

| Pulley Length | 500-3200mm (19-125.9 inch) |

| Diameter | 200-1800mm (7.8-70.8 inch) |

| Standard | ISO9001:2008, CEMA, DIN, TUV, JIS, AS/NS, etc. |

| Working Life | More than 30,000 hours. |

| Surface | 1. Flat Rubber Lagged 2. Ceramic & Rubber Lagged 3. Diamond Grooved Rubber Lagged 4. Chevron Pattern Rubber Lagged 5. Spiral Grooved Rubber Lagged 6. Others |

| Main Material | Carbon Steel Shell |

| Lagged Thickness | The popular thickness is 6mm, 9mm, 12mm, 19mm, 25mm and larger (Customizable). |

| Length of conveyor Lagged pulley depends on the width of conveyor Belt. You can get Lagged pulleys with hot vulcanized rubber lagging, plain or grooved, as required by client. | |

60000

Factory (㎡)

100+

Workers

20+

R&D Engineers

20+

Welders Certified

160+

Marketing Areas

1000+

Projects

When you leave a message on this website, please provide your country name or phone number including the country code. If you have WhatsApp Number, please show us too. This way we can get in touch with you faster.