A motorized pulley, also known as a drum motor, is a type of conveyor drum pulley that includes an integrated electric motor, gearbox, and other components within the pulley shell. It would not be affected by dust, water, oil, grease or other harmful substances. We offer quarry duty and mine duty motorized pulley for sale.

The versatility and efficiency of motorized pulleys make them suitable for a wide range of applications across different industries. Motorized pulleys offer a modern and efficient solution for belt conveyor drive systems, providing benefits in terms of space savings, energy efficiency, and reduced maintenance. Our motorized pulleys are used in major applications like mining, cement, quarries, port, recycling, and demolition.

A flameproof motorized drum pulley is a specialized type of motorized drum pulley designed to meet stringent safety standards for use in environments where there is a risk of flammable gases, vapors, or dust. It is widely used in conveying coal, sugar, etc. And it suits for underground mining conveyor.

Normal Motorized pulley just takes a smaller space than traditional driving pulley. It is suitable for modern bulk materials handling system of different industries like mining, port, power, quarry, etc. We can offer mine duty and quarry duty motorized conveyor pulleys.

| Belt Conveyor Motorized Drum Pulley (Motor Drum) | |

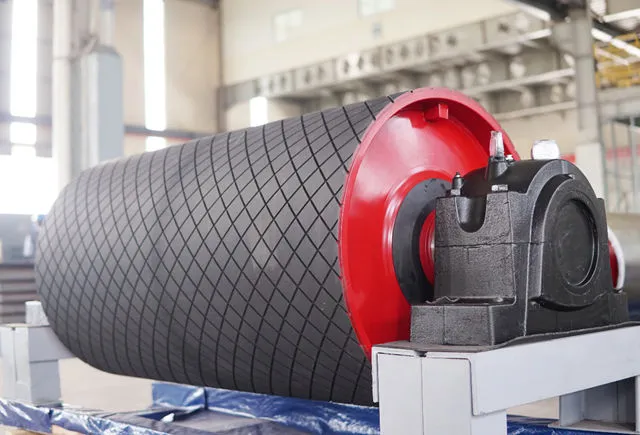

| Component | The Motorized Conveyor Drum Pulley includes pulley shell, bracket, coupler, motor and gear reducer. |

| Types | We provide Flameproof and Normal type motorized conveyor pulleys. They are all oil-cooled drum pulleys. 1. Drum Motor With Internal Motor and Gearbox 2. Drum Motor With External Motor and Gearbox Compact 3. Drum Motor With Gear-less Motor 4. Drum Motor with VFD Control Ability |

| Driving Power | 1.5~630KW(Customizable) |

| Velocity | 0.35~4.0(m/s)(Customizable) |

| Belt Width | 400mm-2600mm(Customizable) |

| Drum Diameter | 200mm-1800mm(Customizable) |

| Type conveyor | Belt Conveyor, Mobile Conveyor, Stacking Conveyor, Mobile Shiploader, etc. |

| Surface | Smooth steel surface, rubber faced, rubber lagged, ceramic lagged, diamond rubber covered. |

| Standard | ISO9001:2008, CEMA, DIN, TUV, etc. |

| Application | Used in mining, coal mine, steel industry, cement industry, aggregate industry and so on. |

| Service life | More than 30,000 hours. |

60000

Factory (㎡)

100+

Workers

20+

R&D Engineers

20+

Welders Certified

160+

Marketing Areas

1000+

Projects

When you leave a message on this website, please provide your country name or phone number including the country code. If you have WhatsApp Number, please show us too. This way we can get in touch with you faster.