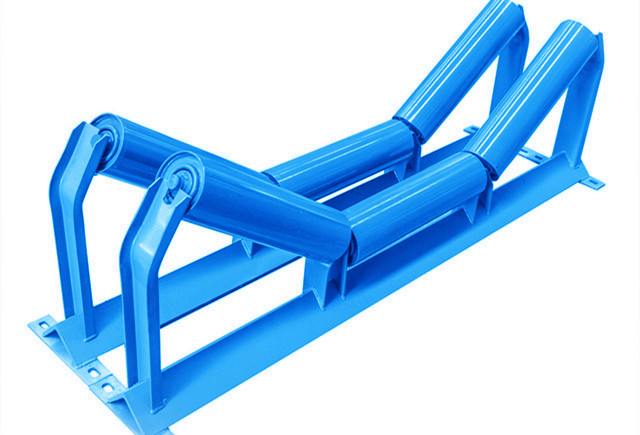

We are conveyor troughed idlers manufacturer in China. Troughed idlers come in various types, including three-roll, five-roll, and six-roll configurations, depending on the design and requirements of the conveyor system. We provide troughing idlers and self-aligning troughed idlers for sale.

Troughed idlers are positioned on the carrying side of the conveyor belt and are responsible for supporting the bulk material being conveyed. They help create a trough shape in the conveyor belt, which is especially useful for handling materials that are prone to spillage. Extending their life expectancy can be a challenge. Our proven seal design and low maintenance rollers lead to less downtime and increased profits. The trouging angle come in 20°, 35°, and 45°.

The troughed carry idler is used to support the upper conveyor belt. Troughers are the most common idlers used on the carry side of the conveyor. Our troughing idlers come in 20°, 35°, and 45°.

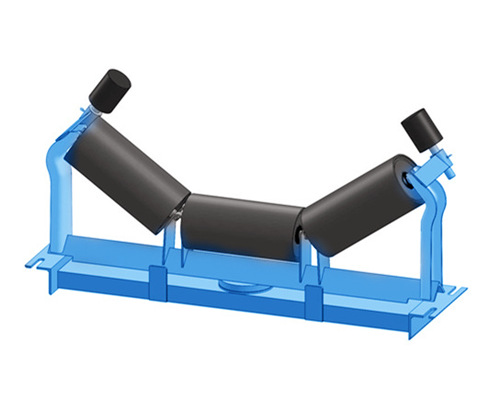

The troughed impact idler is used to reduce the impact of loading point. Damaged conveyor belts can result in downtime and high replacement costs. Our impact idlers are designed to be used in impact areas where belt damage is common.

When conducting visual or magnetic inspections, conveyed materials that are not properly flattened can cause issues. Our picking table idlers spread the material out by using a longer center roll and short concentrator rolls angled at 20° making inspection or tramp iron detection easier and more reliable.

It is used to prevent deviation of conveyor belt. Material spillage can occur when conveyor belts become misaligned. Strategically placing self-training idlers along the conveyor keep the belt running true.

It is the same to troughing training idler but it use the friction rollers as the supporting rollers. This troughed friction idlers don't need guide rollers to algin conveyor belt.

| Specification of Conveyor Troughed Idlers | |

| Trough Idler Type | Belt Width (mm) |

| V-type Carrying Trough Idler (2 rollers) | 300 - 800 |

| Carrying Trough Idler (3 rollers) | 400 - 2200 |

| Self-aling Trough Idler (3 rollers) | 400 - 2200 |

| Trough Friction Idler, Self-aling Idler | 400 - 1400 |

| Trough Tapered Idler, Self-aling Idler | 800 - 2000 |

| Standard | DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc. |

When you leave a message on this website, please provide your country name or phone number including the country code. If you have WhatsApp Number, please show us too. This way we can get in touch with you faster.