Conveyor Impact idler is used to absorb the shock of loaded material from chute at loading and transfer point, so as to protect belt from damage or deterioration. In order to ensure good bonding strength, the impact rubber rings are made of wear and impact resistant rubber are vulcanized.

Conveyor Impact idler is used for receiving material of belt conveyor to reduce and slow impact for conveyor belt, mainly designed for coal washing plant, coking plant, chemical plant and other corrosive environment. Impact roller has good corrosion resistance, if used in corrosive occasions, its service life can be five times than ordinary roller.

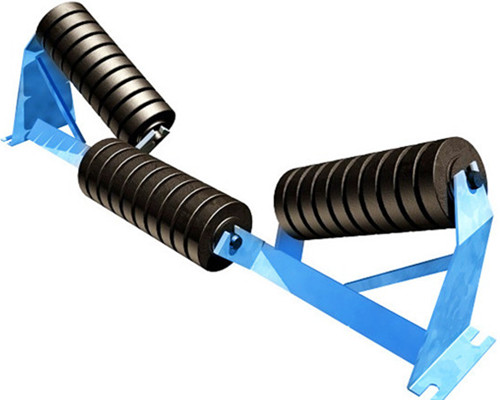

It is used in troughing belt conveyor. There are 3 impact rollers.

It is used in flat belt conveyor. There is 1 impact roller.

The middle impact idler is not in line with others. There are 3 impact rollers.

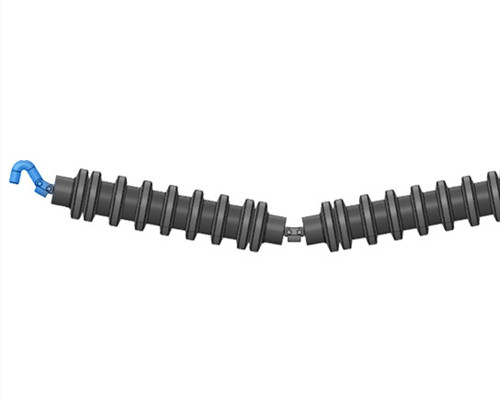

The Garland Impact Idler is hanging to conveyor frames. There are 2 impact rollers.

| Specification of Conveyor Impacty Idlers | |

| Carrying Idler Type | Belt Width (mm) |

| V-type Impact Idler (2 rollers) | 300 - 800 |

| Carrying Impact Idler (3 rollers) | 400 - 2200 |

| Carrying Impact Idler (1 roller) | 300 - 2000 |

| Standard | DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc. |

When you leave a message on this website, please provide your country name or phone number including the country code. If you have WhatsApp Number, please show us too. This way we can get in touch with you faster.