We are conveyor troughing roller sets manufacturer in China. We provide troughing rollers for sale. Are you looking for conveyor troughing roller now? You can get a quotation now.

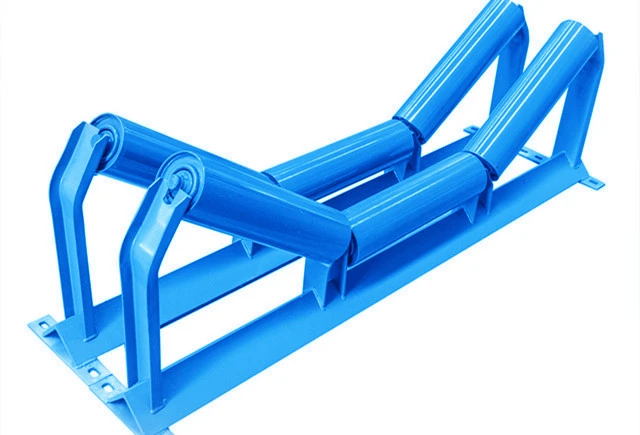

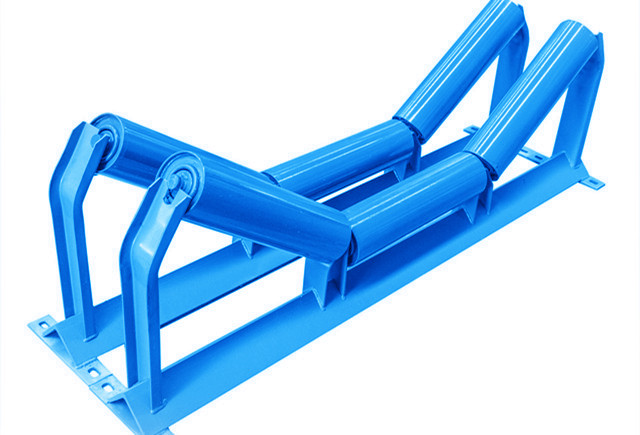

Troughing rollers are the most common conveyor rollers used on the carry side of the conveyor. Our proven seal design and low maintenance rollers lead to less downtime and increased profits. SKE's conveyor troughing rollers come in 20°, 35°, and 45° and meet all dimensional requirements.

The troughed carry roller is used to support the upper conveyor belt.

The troughed impact roller is used to reduce the impact of loading point.

When conducting visual or magnetic inspections, conveyed materials that are not properly flattened can cause issues.

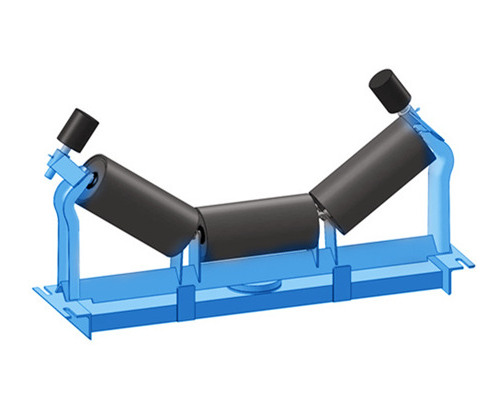

It is used to prevent deviation of conveyor belt.

It is the same to self-align training roller but using friction rollers.

| Specification of Conveyor Troughing Rollers | |

| Trough Roller Type | Belt Width (mm) |

| V-type Carrying Trough Roller (2 rollers) | 300 - 800 |

| Carrying Trough Roller (3 rollers) | 400 - 2200 |

| Self-aling Trough Roller (3 rollers) | 400 - 2200 |

| Trough Friction Roller, Self-aling Roller | 400 - 1400 |

| Trough Tapered Roller, Self-aling Roller | 800 - 2000 |

| Standard | DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc. |

When you leave a message on this website, please provide your country name or phone number including the country code. If you have WhatsApp Number, please show us too. This way we can get in touch with you faster.