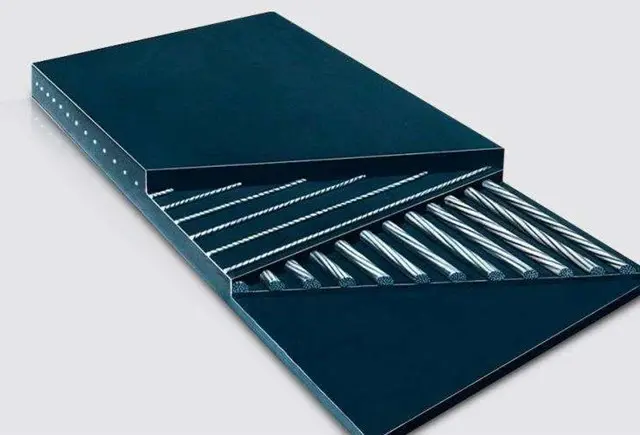

Steel cord conveyor belts have proved to be a very reliable and cost-efficient mode of bulk material handling in long distance conveyors. SKE provide transverse reinforcementand, embedded sensor coil and normal type steel cord belt conveyor belt.

Steel cord conveyor belt (steel wire rope core conveyor belt) is extensively applied in coal mines, Lignite mines, Aluminium mines, Copper mines, ports, metallurgy, power stations, steel industries, Ore Handling Plants, Cement Industries, chemical sectors for long-distance, large amount and high-speed conveying of materials.

The steel cord conveyor belt can be divided into ordinary type, flame-retardant type, heat-resistant type, wear-resistant type, cold resistant type, acid and alkali resistant type, oil resistant type, etc. according to the covering rubber performance. According to its composition, we can divide it into normal type, transverse reinforcement, and sensor line loop embedded steel wire core conveyor belt.

1. High Tensile Strength: steel cord conveyor belt is suitable for transferring materials with long-distance, high intensity and large load.

2. Small Elongation In Use: a very short take-up stroke distance needed.

3. High Adhesion: the steel cord is coated with zinc on the surface, highly adhered to the special core rubber to resistant to heavy impact.

4. Good Trough Ability: as the belt body has no transverse carcass, it is easy to form a deep trough to load more materials without a leak.

5. Smaller Diameter of Driving Pulley: the belt body has a layer of longitudinally arranged steel cords as its carcass to resistant to flex fatigue. Therefore, driving pulley with a smaller diameter can be used to reduce energy consumption.

6. Even Tension of Steel Cords: thanks to our advanced techniques in manufacturing, the steel cords are very evenly arranged with the same tension, so the belts are well balanced in running and difficult to run away.

| Type | Data | Thickness |

| St500 | Operation Tension(N/mm) = 75 Standard diameter (mm) = 2.7 Max. diameter(mm) = 3.0 Min. Cord strength(kN) = 6.9 Cord pitch(mm) = 12.0 |

4/4 |

| St630 | Operation Tension(N/mm) = 90 Standard diameter (mm) = 2.8 Max. diameter(mm) = 3.0 Min. Cord strength(kN) = 6.9 Cord pitch(mm) = 10.0 |

4/4 |

| St800 | Operation Tension(N/mm) = 110 Standard diameter (mm) = 3.1 Max. diameter(mm) = 3.5 Min. Cord strength(kN) = 8.8 Cord pitch(mm) = 10.0 |

4/4 |

| St1000 | Operation Tension(N/mm) = 140 Standard diameter (mm) = 3.7 Max. diameter(mm) = 4.0 Min. Cord strength(kN) = 13.2 Cord pitch(mm) = 12.0 |

5/5 |

| St1250 | Operation Tension(N/mm) = 175 Standard diameter (mm) = 4.2 Max. diameter(mm) = 4.5 Min. Cord strength(kN) = 16.5 Cord pitch(mm) = 12.0 |

5/5 |

| St1400 | Operation Tension(N/mm) = 200 Standard diameter (mm) = 4.4 Max. diameter(mm) = 4.8 Min. Cord strength(kN) = 18.5 Cord pitch(mm) = 12.0 |

6/6 |

| St1600 | Operation Tension(N/mm) = 225 Standard diameter (mm) = 4.7 Max. diameter(mm) = 5.0 Min. Cord strength(kN) = 21.1 Cord pitch(mm) = 12.0 |

8/6 |

| St1800 | Operation Tension(N/mm) = 255 Standard diameter (mm) = 5.1 Max. diameter(mm) = 5.5 Min. Cord strength(kN) = 24.2 Cord pitch(mm) = 12.0 |

8/6 |

| St2000 | Operation Tension(N/mm) = 28.5 Standard diameter (mm) = 5.5 Max. diameter(mm) = 6.0 Min. Cord strength(kN) = 26.4 Cord pitch(mm) = 12.0 |

8/6 |

| St2250 | Operation Tension(N/mm) = 320 Standard diameter (mm) = 5.7 Max. diameter(mm) = 6.2 Min. Cord strength(kN) = 30.0 Cord pitch(mm) = 12.0 |

8/6 |

| St2500 | Operation Tension(N/mm) = 355 Standard diameter (mm) = 6.8 Max. diameter(mm) = 7.2 Min. Cord strength(kN) = 41.2 Cord pitch(mm) = 15.0 |

8/6 |

| St2800 | Operation Tension(N/mm) = 400 Standard diameter (mm) = 7.3 Max. diameter(mm) = 7.8 Min. Cord strength(kN) = 46.0 Cord pitch(mm) = 15.0 |

8/6 |

| St3150 | Operation Tension(N/mm) = 450 Standard diameter (mm) = 7.6 Max. diameter(mm) = 8.1 Min. Cord strength(kN) = 51.9 Cord pitch(mm) = 15.0 |

8/8 |

| St3500 | Operation Tension(N/mm) = 570 Standard diameter (mm) = 8.0 Max. diameter(mm) = 8.6 Min. Cord strength(kN) = 57.1 Cord pitch(mm) = 15.0 |

8/8 |

| St4000 | Operation Tension(N/mm) = 570 Standard diameter (mm) = 8.6 Max. diameter(mm) = 8.9 Min. Cord strength(kN) = 66.0 Cord pitch(mm) = 15.0 |

8/8 |

| St4500 | Operation Tension(N/mm) = 645 Standard diameter (mm) = 9.1 Max. diameter(mm) = 9.7 Min. Cord strength(kN) = 79.2 Cord pitch(mm) = 16.0 |

8/8 |

| St5000 | Operation Tension(N/mm) = 715 Standard diameter (mm) = 10.5 Max. diameter(mm) = 10.9 Min. Cord strength(kN) = 93.5 Cord pitch(mm) = 17.0 |

8.5/8.5 |

| St5400 | Operation Tension(N/mm) = 760 Standard diameter (mm) = 10.8 Max. diameter(mm) = 11.3 Min. Cord strength(kN) = 101.0 Cord pitch(mm) = 17 |

9/9 |

| St5800 | Operation Tension(N/mm) = 830 Standard diameter (mm) = 11.5 Max. diameter(mm) = 11.8 Min. Cord strength(kN) = 109.0 Cord pitch(mm) = 17 |

10/10 |

| St6300 | Operation Tension(N/mm) = 900 Standard diameter (mm) = 12.0 Max. diameter(mm) = 12.3 Min. Cord strength(kN) = 118.0 Cord pitch(mm) = 17 |

12/10 |

| St6700 | Operation Tension(N/mm) = 950 Standard diameter (mm) = 12.7 Max. diameter(mm) = 13.0 Min. Cord strength(kN) = 133.0 Cord pitch(mm) = 18.0 |

12/10 |

| Wear Resistant | Data | Characteristics |

| X | Min.Tension N/mm =25 Max. Abrasion mm³=120 |

Heavy-duty cover for coarse and sharp material Resistant against impacts and cuts. Complies with: X (DIN), RMA1, H (ISO), M (AS), M24 (BS) |

| Y | Min.Tension N/mm =20 Max. Abrasion mm³=150 |

Wear-resistant cover for normal operating conditions Complies with: Y (DIN), RMA 1&2, L (ISO), N (AS), N17 (BS) |

| W | Min.Tension N/mm =18 Max. Abrasion mm³=90 |

Cover with excellent resistance against erosive wear For small-sized, abrasive material Complies with: W (DIN), RMA 1&2, D (ISO) |

| Flame Resistant | Data | Characteristics |

| K | Min.Tension N/mm =20 Max. Abrasion mm³=200 |

Abrasion-resistant cover with flame-resistant characteristics according to ISO 340 |

| VT | Min.Tension N/mm =17 Max. Abrasion mm³=175 |

Cover with fire-resistant properties according to DIN |

| Heat Resistant | Data | Characteristics |

| T120 | Min.Tension N/mm =15 Max. Abrasion mm³=175 |

Heat-resistant, abrasion-resistant cover for temperatures up to 120 °C |

When you leave a message on this website, please provide your country name or phone number including the country code. If you have WhatsApp Number, please show us too. This way we can get in touch with you faster.